Author Archive

Antenna-Day #1, in My Son’s Words

Antenna-Day #1, in My Son’s Words

As my son’s homeschool teacher I’m giving him plenty of writing assignments this year. Yesterday I asked him to write an essay, and I told him he could write it on anything he wanted. Here’s what he wrote:

Helping Dad Build His Antenna

by Antonio Mitchell, Tuesday, October 11, 2011My dad has been meaning to build his antenna for his radio for a while. We (my dad and I) finally got motivated and had some free time as well to build the antenna. We began yesterday to build it. Some complications slowed us down.

Yesterday, we went to Wilmar. The first stop was Walmart. When we were in Walmart I got my glasses back. After that we began our search for parts at Menards. It took us a while to find some parts. The whole trip to Wilmar, shopping, and going home took quite a few hours. My dad had to meet with a church member. While he was gone he got a piece of metal cut for the tripod legs.

When he came home several hours later my mom and I were raking leaves. He began to put together a jig to help hold the poles together. We began to drill holes into the poles. It took both of us to do it. The bit finally broke. After supper my dad worked on making a balun. He also made a new shopping list of parts. It will be a great joy to see the antenna up on our roof.

Enough Planning! It’s Time to Put This Antenna Up!

Enough Planning! It’s Time to Put This Antenna Up!

Hopefully Monday will be an antenna-building day. I don’t know that it will all come together in one shot, but if I don’t get this project going it’s never going to get done.

I spent some time in the hardware store yesterday, picking out the many different bits and pieces that I’ll need for the job. Hard to believe how much it all added up to. Gulp! At least I had a coupon for $10 off of my purchase. As it is there are still a couple more little things I need, but I’ll have to drive up to Willmar for those on Monday.

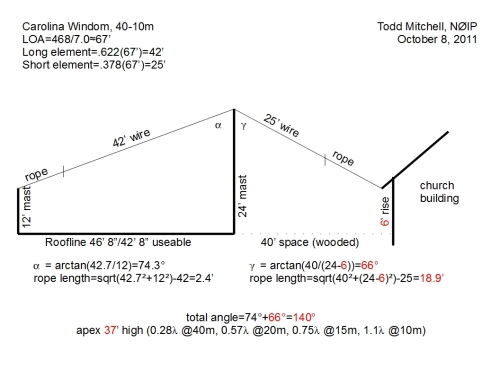

Here’s a rough sketch that I made last March, dusted off and updated slightly. There are still a couple of unknowns — those are the figures in red. I’m not certain that I’ll need to attach anything to the adjacent church-building, since I may get away with just draping the wire in a nearby tree. But I’ll figure that out as I go. I’ve planned enough! It’s time to put this antenna up!

I’m not certain that I’ll need to attach anything to the adjacent church-building, since I may get away with just draping the wire in a nearby tree. But I’ll figure that out as I go. I’ve planned enough! It’s time to put this antenna up!

Of Pounding Ground Rods and Labeling a Field Box

Of Pounding Ground Rods and Labeling a Field Box

My arm is tired! I pounded in a ground rod tonight, a stout 8-footer from Fleet Farm. It wouldn’t have been so bad if it had gone in on the first try, but it took me three tries before I found a spot that didn’t have some obstruction about four feet under ground! (Remember I live in Granite Falls. There’s lots of rock around here.) I’m not sure which was harder — swinging the sledge hammer until the rod got stuck, or trying to pull the crazy thing out of the ground when it did. Soaking the ground with water helped to get it out in one instance.

It’s tempting to soak the ground with water before pounding your ground rod in, to make it sink in easier, but I’ve read that you shouldn’t do that as you wind up with a poor connection after the soil dries. As with many other things, the easy way isn’t always the best way.

Anyhow, I finally got it in far enough. There’s about ten inches sticking up out of the ground still, but all I’m doing by swinging at it now is flattening out the top. Once my wife hides it with a hosta plant it will look just fine! I tried pounding in a second one, but when it got stuck and I had to work it out (by clamping vicegrips on it and prying it out with a crowbar, a few inches at a time), I called it a day.

Much easier and more satisfying was labeling the toolbox I’ve converted into a field-kit: I’m asking an awful lot of this decal, sticking it on a pebbled surface. But so far it’s sticking just fine. Randy George, N3ZK, does a great job on these, ships them fast, and the price is right! For only $4.00 (shipping included) you get three of these labels.

I’m asking an awful lot of this decal, sticking it on a pebbled surface. But so far it’s sticking just fine. Randy George, N3ZK, does a great job on these, ships them fast, and the price is right! For only $4.00 (shipping included) you get three of these labels.

In the field box right now is my Heathkit HW-8 and all the accessories necessary to zip out to my picnic table and get on the air with my low-hanging, temporary OCF dipole. Pretty soon it will be too cold to do that comfortably! That’s why I’m pounding ground rods, trying to get my long-awaited New Carolina Windom up and going before the ice and snow comes.

Basic CW Operating Procedures

Basic CW Operating Procedures

Back when I first got on the air in 1978, CW QSO’s had a pretty standard format. That format didn’t change much until the last few years. But today there’s quite a hodgepodge of operating procedures out there. Most of the time it works, but it’s not uncommon to hear a downright jumbled mess — even from a CW operator who has been on the air long enough to send and receive at 10 wpm or more.

It’s important to learn good operating procedure, not just because it sounds polished but because it serves a practical purpose. You can get away with sloppy operating procedure under perfect conditions, but not if your signal is weak or if there’s much QRM, QRN, and/or QSB. Even under perfect conditions, you’re making the person at the other end work harder if you’re constantly surprising him with your own odd way of operating. Under poor conditions, he may miss some of what you’re trying to say. And even if he succeeds at copying what you’re saying he may well be relieved when the ordeal is over.

I’m not going to get into all of the details of good operating procedure here, but I would like to discuss some basics.

General structure

There is a general structure to a CW QSO that most operators expect. After establishing contact, the first transmission should stick to the basics — RST, QTH, and name. You don’t know yet how well the other fellow is copying you; if you’re a 329, you’re going to torture him if you go on and on about your rig, your power, your antenna, the weather, etc. Furthermore, you might lose the opportunity to hear even the basics from the other fellow if band conditions deteriorate while you’re sending all this on the first transmission. So stick to the basics — and do send them. Here’s the way we all used to do it years ago:

NØART DE NØIP R TNX FER CALL OM BT UR RST RST 579 579 BT QTH QTH GRANITE FALLS, MN GRANITE FALLS, MN BT NAME NAME TODD TODD BT SO HW CPY? AR NØART DE NØIP KN

Note the use of BT. That seems to have fallen out of favor, but once upon a time it was the standard way of changing the subject. The most important thing I want to point out here is to preface each of the three major elements of this first transmission with their labels: RST, QTH, and NAME. It takes a few seconds longer than sending something like, “UR 579 IN GRANITE FALLS, MN OP TODD,” but it is worth it. As the FISTS club puts it, “Accuracy transcends speed.”

The operator replying to this first transmission sends the same three basics in the same way. If he’s inclined (and if he’s received a reasonably good RST) he will probably go on to talk about his station, the weather, etc. As it turns into a ragchewing session you can pretty much send whatever you want.

Procedure signals

Just as the use of BT has fallen out of favor, so have other procedure signals fallen on hard times. I often hear them sent incorrectly and used improperly. Remember what these are — they are procedure signals. Learn to send them well and to use them well, and your operating procedure will improve substantially. The ones most commonly used are AR, AS, BK, BT, K, KN and SK.

Notice the line that appears over each one of the two-letter procedure signals. That means you send the two letters as if they are one character. For instance, KN isn’t sent as dah-di-dah dah-dit (KN) but dah-di-dah-dah-dit (KN).

- AR End of message: Send this after you are completely done sending everything — everything, that is, but call signs and KN. If it’s your last transmission, use SK instead.

- AS Wait:You might hear this if you’re working an experienced operator. If you hear this, the next thing you hear will probably be silence — maybe he has to answer the phone or something. Or maybe you’ll hear him hold his key down while he fiddles with his antenna tuner. Don’t start sending — he’ll start sending when he’s ready. This is a handy procedure sign to know, if you ever need to take a break yourself.

- BK Break: This might be used by a station who wants to enter an ongoing QSO — he’ll send BK between transmissions to see if they’ll let him in and turn their QSO into a “roundtable.” With the advent of full QSK keying, this also became popular among experienced CW operators who could interrupt one another right in the middle of a transmission (perhaps to answer a question or clarify something). But most commonly BK is used to rapidly turn the conversation over to the other station without sending any call signs. For instance, an operator might send something like “HOW CPY? BK” and then cease his transmission. If this happens to you, reply by simply sending BK and answer his question. You can go back and forth in this manner for as long as you want, but don’t forget to obey the law by identifying yourself with your call sign at least every 10 minutes.

- BT Separator: Usually used to change the subject, even if it’s just to go from sending RST to sending QTH. (If you hear the other fellow sending BT several times, it’s because he’s trying to think of what he wants to say next!)

- K Over: This invites anybody listening to reply. Send this after you’re done calling CQ. But if you’re in a QSO, you almost always want to use KN, not K.

- KN Over (to specific station): Send this after signing over to the other station in a QSO, e.g. NØART DE NØIP KN. KN tells other listeners that they’re not welcome to call you yet — you just want the station you’ve named to reply. Don’t send this after calling CQ — send K instead.

- SK End of contact: This lets the other operator know that you want to end this QSO, and this is your last transmission. Usually sent in place of AR right before signing over to the other station.

The Handshake

It has long been customary to send “dit dit” at the very end of a QSO, like a final handshake. On the very last transmisssion, the sending station sends “dit dit” and then the other station replies “dit dit,” and that’s the end. Or (like we did in the old days) you’ll hear the first station send “dit di-di-dit dit” and wait for the second station to send “dit dit” (“shave and a haircut, two bits!”).

But this is often fumbled. Here’s how it usually goes wrong. The first station to send his final farewell, e.g. TNX FER QSO HPE CU AGN 73 73 SK NØART DE NØIP KN, knowing full well that the other station still plans on bidding him farewell in the same manner, goes ahead and sends “dit dit” at the end of his transmission. Naturally, the other station ignores this faux pas, goes on to send his last transmission, and only when he is done does he finally offer “dit dit” for the other operator to send his own “dit dit” again.

Now, this is obviously not the most important point of operating procedure, but why not do it right? No need to be socially awkward at the end of a good QSO!

I’ve only covered a few basics here. For more on CW operating procedures, it’s worth checking out something like http://www.fists.org/basiccw.html. But the best way to learn good operating procedures is simply to pay attention to what proficient operators are doing — especially as you get into more advanced operation, like handling DX pileups. The more listening you do before you wade in, the better operator you will be.

Teaching Morse Code: The Importance of Perfect Dits and Dahs

Teaching Morse Code: The Importance of Perfect Dits and Dahs

My son and I had another lesson this evening before bedtime. This time I dug out my paddles and my electronic keyer, since I was afraid that my imperfect fist at the straight key could do him damage.

My fears were well placed!

It turns out that in our first lesson I made my “dahs” much too long. This caused him some grief when I started using my electronic keyer since the “dahs” and the “dits” sounded too much alike to him, accustomed as he was to my goofy fist (which shall now be rectified ASAP!).

So we spent most of this lesson just fixing my mistake, getting my son to discern between perfectly proportioned “dits” and “dahs.”

I’m glad we caught my mistake on this second lesson and not several months from now! But I still feel bad for exasperating my son.

So to all you would-be Morse Elmers out there, learn from my mistake! Whatever quirks you may have in your fist may be exacerbated at low speed. So unless you have a perfect fist with a straight key, use your electronic keyer right from the beginning when teaching Morse Code.

Teaching and Learning Morse Code: The Personal Method

Teaching and Learning Morse Code: The Personal Method

There are all sorts of ways to teach Morse Code. There’s the old Army way (check out these youtube clips: part 1, part 2). Then there’s the way the ARRL taught me back in 1978 — with cassette tapes. And today, students can download software that will teach them Morse Code with the Farnsworth Method and the Koch Method. It all works, so long as the student sticks with it.

How do you get a student to stick with it? First and foremost, by cultivating within him an affection for Morse Code. As Antoine de Saint-Exupery purportedly said, “If you want to build a ship, don’t drum up people to collect wood and don’t assign them tasks and work, but rather teach them to long for the endless immensity of the sea.”1 But since so many things can thwart this affection (from discouragement to competing interests), sometimes you simply need to come alongside the student and encourage him. This is where cassette tapes and computer programs usually fall short. There’s nothing like The Personal Method — a real, live Elmer teaching you Morse Code.

Just ask my son! A few days ago I purchased a nifty Nye Viking Speed-X straight key and code practice oscillator to begin teaching him Morse Code.  I hooked up my own Speed-X to it so that we could both key the oscillator — him on one side of the table with his new practice set, and me on the other side of the table with my own key. Thus equipped, we had our first lesson before bedtime Wednesday night.

I hooked up my own Speed-X to it so that we could both key the oscillator — him on one side of the table with his new practice set, and me on the other side of the table with my own key. Thus equipped, we had our first lesson before bedtime Wednesday night.

I was surprised by how hard the bug bit him. At first he wasn’t so sure about the whole thing, but by the end of the lesson he was so excited he said he wouldn’t be able to get to sleep. He even told me that he wouldn’t enjoy his classical guitar lesson and horse-riding lesson quite as much the next day because he just wanted to have the next Morse Code lesson! The next morning, he woke me up by sending “GM” outside my door with this practice set. And later in the day, he started sending me code as went down the road, saying “dit” and “dah” like a true CW operator.

I was surprised by how hard the bug bit him. At first he wasn’t so sure about the whole thing, but by the end of the lesson he was so excited he said he wouldn’t be able to get to sleep. He even told me that he wouldn’t enjoy his classical guitar lesson and horse-riding lesson quite as much the next day because he just wanted to have the next Morse Code lesson! The next morning, he woke me up by sending “GM” outside my door with this practice set. And later in the day, he started sending me code as went down the road, saying “dit” and “dah” like a true CW operator.

So to my fellow CW operators who know somebody that wants to learn Morse Code, I say let’s try The Personal Method. And to those of you who do want to learn Morse Code, try to find an Elmer who is willing to spend some time with you. If you can’t find one who can meet with you, hang in there with your cassette tapes or your computer program until you know enough code to work with an Elmer on the air. As the SKCC website says, “If you can only key at 3 words per minute, so be it.” There are SKCC Elmers who are eager to work with you (http://www.skccgroup.com/elmers.php). You’ll be amazed at how quickly you build up your speed, and you’ll enjoy the experience a thousand times more than by trying to learn all by yourself.

1 This quote is all over the Internet, but I’ve yet to see any citation for it. If you know where Antoine de Saint-Exupery wrote this, please let me know!

How to Make an Attractive, Heavy Base for a Straight Key

How to Make an Attractive, Heavy Base for a Straight Key

My friend is getting back into ham radio for the first time since he was a boy, and one of the first things he wants is a straight key. I’ve steered him toward the Nye Viking Speed-X key. You can spend lots of money on keys nowadays, and I admit that some of them are mighty pretty. But the eham reviews of the Speed-X key suggest that looks aren’t everything. Unless you’re willing to spend a fortune for a luxury-model, I say put your money on the Speed-X. It’s worth every penny.

Probably the best way to mount this key is to screw it down to your desk if you’re willing to. Or you can buy a nice heavy aluminum base for this key straight from Nye Viking. But here’s how you can make an attractive, heavy base for not a whole lot of money. Here’s the finished product (I made this years ago):

I found this inexpensive piece of wood at Michael’s (an arts and crafts store). It was unfinished with the edges already routed as shown. When you find your own piece of wood like this, figure out where you want to mount your key. I used nuts and bolts to mount my key, but wood screws probably would have been better (by the time you’re done with this project, you’ll have a hard time getting to any nuts on the underside because they will be covered with felt). If you do decide to use nuts and bolts, drill holes for the bolts now so that you know where those holes are in the next step.

Flip the piece of wood upside down and go to work hollowing out as much of it as you can, starting about a half inch in from each edge. I can’t remember if I used a chisel, a Dremel tool, or both, but either would work. Just be careful not to hollow out so much that you punch through to the other side! Leave enough wood in the spots where you’re going to bolt or screw down your key so that you have a good strong mount when you’re done.

Once you hollow out the underside of your piece of wood, take a hot glue gun and glue in as much lead shot as you can stuff in there. This is what makes the base nice and heavy so that your key doesn’t jump around while you’re pounding out CW.

Give the block of wood a quick sanding, stain it with your favorite stain, varnish it, and mount your key! If you are using nuts and bolts, I recommend using a bit of Locktite to keep them from coming loose.

The last step is to glue a piece of felt to the underside of the block of wood. This hides the unsightly gob of lead shot and glue you’ve put in there, and it lets you slide the thing around on your desk smoothly. Don’t worry, it won’t make it too slippery. If you’ve put enough lead shot in there it will stay put just fine while you’re pounding brass. Here’s a look at the underside of mine:

If you build one of these yourself, let me know! I’d love to hear from you.

Items required:

Wooden base (available from craft store)

Felt (also available from craft store)

Lead shot (available from sporting goods store)

Nuts & bolts (or wood screws) to mount key

Dremel tool and/or wood-chisel

Hot glue gun

Wood Stain

Varnish