Posts Tagged ‘Construction’

Simple keyer trouble

Simple keyer trouble

It should have been simple. I needed a basic CW keyer that would allow me to use a paddle with my homebrew QRP / QRPP rigs because my shaky hands make sending Morse with a straight key too difficult at the moment. I also needed to be able to record a message and play it once or repeatedly until I heard someone reply or was spotted on the reverse beacon network.

A couple of years ago I built a DC20B QRP transceiver. I didn’t like it very much and eventually sold it on eBay but I did like the keyer built into it which used an ATTiny13 microcontroller. One day, I thought, I would build a keyer using this chip. I got two of the Atmel chips and Steve Weber KD1JV sent me the hex file so I could program them but I never got around to doing anything more until a couple of days ago.

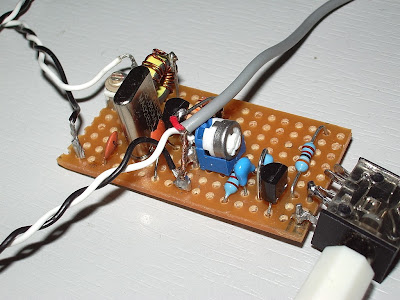

The simple keyer circuit uses only a handful of components but due to my condition it took a lot longer than it would have done pre-tumour to work out a perf board layout and build it. So you can imagine that I was a bit upset when after all that effort the keyer didn’t work. It responded to the dash key and the function button, but not the dot key. Also the sidetone was very high pitched and the Morse speed was about 100wpm!

Thinking I had made a mistake programming the clock setting in the chip I tried programming the other one. This ended up just the same. Unfortunately with the simple keyer program you have to disable the reset pin that is used by the programmer so you only get one chance to write the code to the EPROM. But as I don’t have the source code and so can’t try modifying it that shouldn’t have been a problem. If I hadn’t sold the DC20B I could have tried the keyer chip from that, but now I am now stuck with no idea what to try next.

I have the code for another keyer that uses a PIC12F509A – the K9 from K1EL’s freeware page. But I’d have to start over with the circuit board as the pinouts of the Atmel and Microchip microcontrollers are not compatible. The functionality of the K1EL keyer program is not what I was after either, so I don’t feel much like trying it at the moment.

More EU madness

More EU madness

I’m not the first blogger to mention this item of news but it is certainly one topic that I could not allow to pass by without comment. According to the IARU Region 1 website, the EU Commission will be revising the EMC Directive and removing the exemption of amateur radio kits and modified equipment from its provisions. Products that are currently exempted would be subject to inspection and certification, a process which would make the production of kits hopelessly uneconomic. It would also potentially spell the end of home building and modification and prevent the importation of kits from the USA and other havens of relative sanity. No, this isn’t one of my April 1st spoof stories released from the Drafts folder by mistake!

I’m not the first blogger to mention this item of news but it is certainly one topic that I could not allow to pass by without comment. According to the IARU Region 1 website, the EU Commission will be revising the EMC Directive and removing the exemption of amateur radio kits and modified equipment from its provisions. Products that are currently exempted would be subject to inspection and certification, a process which would make the production of kits hopelessly uneconomic. It would also potentially spell the end of home building and modification and prevent the importation of kits from the USA and other havens of relative sanity. No, this isn’t one of my April 1st spoof stories released from the Drafts folder by mistake!

I would hope that the IARU, the RSGB and other European amateur radio societies will make urgent representations to the EC to stop this proposal. But this is just one scary example of why I and many other like-minded people feel that we in the UK would be better off out of the European Union.

In fact, most of Europe would be better off without it in my opinion. Could somebody explain why, at a time when European governments are supposed to be cutting back on public expenditure, they continue contributing billions every year (only recently having voted an increase – the UK alone contributes £51 million per day) in order to fund this unelected and unaccountable Commission to employ people who live in cloud cuckoo land to produce unwanted, unnecessary and unasked-for legislation?

Not so chirpy

Not so chirpy

Yesterday I attempted to have a QSO using the XBM-10-2 two transistor “Chirpy” transceiver for 10m. I asked Jim, G3XPD, who is about 8km south of G4ILO to listen out for me. Jim could hear the distinctive sound of my 100mW transmission, but I could not hear Jim, not even when he called using 100W.

I know the Chirpy receiver works because I can receive a locally generated signal such as my antenna analyzer. But I guess even that is a big signal compared to one received off the air. I need to find a way to improve the receive sensitivity if it is to be possible to make a real two-way contact using this simple transceiver circuit.

I have tried adjusting C2 for maximum noise in the earpiece rather than maximum output when the key is down, to see if that gives some improvement. If nothing else it seems to have tamed the chirp a bit.

The Basement Project

The Basement Project

While I’ve mentioned it several times on my podcast, I don’t recall blogging much about it. I did blog once about moving my ham shack from a 6 foot area to a larger area here. But for what feels like a decade, I’ve been planning for and slowly working on my new basement ham shack, office and just general man-cave. It all began sometime in early 2008 when I got the idea to turn the un-finished portion of my basement into a new ham shack.

We had half of our basement finished soon after purchasing our house in 2004. It’s been in this finished area where I’ve setup my ham shack, podcast recording studio and home office. Because this basement area was finished prior to me getting my ham ticket, I have to run my coax feed line either across the ceiling or across the carpet to get it to an outside wall. Of course we do what we have to do to get on the air. But I’ve always thought it would be nice to have a space that didn’t have coax and power cords everywhere.

The first step was to move everything from the unfinished area of the basement (primarily used for storage) to the finished area so I could begin construction. The unfinished portion of the basement is concrete floor and concrete walls. While I would have no problem working in a concrete space like this, the object was to create something that was nice and comfortable. So up went the 2×4 stud walls.

The framing portion of the overall project went fairly quickly. The main room of my ham shack/home office/man cave is a room approx. 20’x20’ with a hallway measuring about 8’x16’ opening up into the area that is the laundry room which when framed in was about another 12’ or so of wall space.

While I started the framing project in 2008, if memory serves me correctly all the framing was complete in about 3-4 months. So what have I been doing the past three years? Well obviously not a lot in relation to the basement project.

Part of the delay has been due to life schedule conflicts. You know work, travel, good DX conditions etc. In recent weeks, it has been hard to pry myself away from the radio to go work on the basement. But I really want to get this done and the wife really wants to claim the rest of the basement for other uses.

A few weeks ago I started working on the basement area again. I’ve been running electrical, CATV, telephone and network cables in the new area. With the help of my wonderful wife, we have mapped out where my desk and such will be. I’ll admit I’m not the most tidy person on the planet. My current shack area looks like a bomb went off. I blame this primarily on the fact that I have no cabinet space. Everything is either on the desk, under the desk or stacked beside the desk. The new space will have cabinets under the desk surface and cabinets from the ceiling down with just enough space in between for the work area.

Speaking of work areas. I’ll have my primary operating position in one corner. I’ve worked in a corner type setup for the past couple of years and like having the LCD in the corner with my FT-950 on the right and my FT-897 (used for digi modes) to my left. There will be plenty of space for my VHF/UHF rigs, packet and just about anything else I want to do. I have also factored in a large workbench area where I can build projects and restore those old AM radios which I enjoy.

For the wall material I’m going with sheetrock. While we had investigated other options, we kept coming back to drywall. This will be one area which we’ll contract out and for a couple of reasons. One, it will be difficult for just my wife and I to handle the sheetrock (especially the ceiling) the time to complete the job would take us a few weekends. The sheetrock process is a dirty and nasty one. I can hire a contractor and crew to come in and they’ll hang, plaster, sand and texture the walls in just a few days. My wife and I then will paint and do all the rest.

Back to the cable planning. I’ve factored in both what my present need is as well as looking ahead. Because the exterior wall where I run the coax feed line for my Hustler 6BTV (ground mounted in my back yard) will be covered in sheetrock as well as the ceiling above it, I’ll need a way to access this in the future. I installed a 1 1/2” PVC pipe across the ceiling for my coax needs. Some may argue and say I should have installed a larger pipe, but living in “HOA Hell” I’ll never have a need (nor permission) to install anything other than a vertical antenna in my back yard. I’ll still have access from the utility closet where I’ve pulled the feed line for my 20m hamstick dipole, rotator and VHF/UHF antenna.

The final decision to make is on the floor covering. Everything from just the bare concrete floor to tile has come into our heads. I do know that carpet (any style is out). I want to be able to zoom from one side of my desk to the other in my chair without issue and carpet just doesn’t allow it. Plus carpet in a basement is a bad idea any way you look at it.

I have just another weekend or two of work to do before we can bring in the sheetrock guys. I need to run speaker wire for a surround sound setup and make one more plumbing modification near where the laundry area will be. If all goes as planned, we would like to have the sheetrock installed just prior to Christmas and use some of the time-off to do the painting.

I’ll update everyone in a few weeks on our progress and hopefully with pictures. I don’t see much need in adding photos to this blog article. I think everyone knows what concrete walls with 2×4 studs in front look like.

Until next time….

73 de KD0BIK (Jerry)

Two Transistor Tranceiver for Ten

Two Transistor Tranceiver for Ten

With ten metres opening up it seemed the right time to try building Roger G3XBM’s latest project: the XBM10-2. Roger describes it as probably just about the simplest CW transceiver possible for use on 10m, using just two transistors to produce about 60mW out.

This was my first attempt at construction since my radiotherapy and chemotherapy and I found it to be quite a struggle. First of all I found it difficult to concentrate while trying to work out the perf board layout. After that I got a bit frustrated with constantly juggling three pairs of spectacles due to my eyes apparent inability to focus at different distances. I also found soldering difficult due to my hands shaking whenever I brought the iron bit close to a component. I created quite a few solder bridges which I then had to clean up.

Construction took much longer than I would have taken a few months ago. But in the end it did work. Though not on ten metres yet. I’m waiting for a 28.060MHz crystal from the G-QRP club shop before I can try it out on the air.

One issue I have found (which Roger also comments on) is that the rig has a major chirp. It is definitely not T9 and I don’t know whether it is possible to improve on that. But at least it has character. If you hear a weak, chirpy signal near to the 10m QRP activity frequency give it a call. It might be me!

Long wave goodbye

Long wave goodbye

I never did get the Spectrum Communications Off-Air Frequency Standard kit working. Now it is looking as though it would be a waste of time anyway as the BBC will be closing down the Radio 4 long wave transmitter that is used as a frequency standard.

An article published yesterday in the Guardian Online explains that the Radio 4 long wave transmitter uses valves (tubes) that are no longer obtainable. The BBC has the only ones still in existence. The transmitter uses a pair and they can last as little as one year. When the last valve blows, Radio 4 on long wave will become a thing of the past.

Building a new long wave transmitter using up to date technology would cost millions which the BBC can no longer afford due to the need to cut costs as a result of the government’s decision to freeze the licence fee.

There are many other ways to receive the Radio 4 programming if the long wave transmitter closes down. But none of them involve a powerful 500kW transmitter whose frequency is maintained accurately enough to be used as a frequency standard.

The Dummy Load Projects

The Dummy Load Projects

About two years ago I ordered a QRP Wattmeter kit from Oak Hills Research (OHR). The kit contained everything I would need to complete the project and in a few hours over the course of about 2 days I had it fully assembled, tested and working. Prior to this kit, I hadn’t done this kind of work since high school.

I was actually very fortunate that while in high school, my band director Mr. Crawford NB5I put together a basic electronics and computer class. I’m thinking this was either in my sophomore or junior year (1983-84). This was in the timeframe when I was really interested ham radio and my off and on again attempts at learning CW. The class was a welcome change to the reading, writing and arithmetic classes which I’ll admit did bore me. It was really my intention to take this electronics class to help better assist me in learning all that a novice class amateur would need to know back then. I remember two things about this class. One, I built a cool 12v power supply. We had to design the project, etch the circuit boards, solder in all the parts and for it to work. Mine did. The second thing I remember about that class was burning the snot out of my first two fingers and thumb from accidentally grabbing the soldering iron at the wrong end. Thank you Mr. Crawford for teaching this class.

Now skip forward some 25+ years, I had a ball putting that QRP wattmeter together and to find that it worked in the end with no burns on my fingers was all I needed. I had been bitten by the bug. I ordered a few additional kits from OHR. These were two 10w dummy loads and one 100w dummy load. The 10w models are pictured just sitting on top of the 100w dummy load. These 10w models are great for the QRP rig.

Now skip forward some 25+ years, I had a ball putting that QRP wattmeter together and to find that it worked in the end with no burns on my fingers was all I needed. I had been bitten by the bug. I ordered a few additional kits from OHR. These were two 10w dummy loads and one 100w dummy load. The 10w models are pictured just sitting on top of the 100w dummy load. These 10w models are great for the QRP rig.

I’ll admit I started the 100w model about a year ago. I managed to get ten of the twenty resistors soldered onto the board and life got busy and I moved it to the side of my workbench. I’ve looked over at it several times and even grabbed the soldering iron a few times only to put it back with either no time or no interest to complete it.

Now that I have extra under my belt, I thought it was about time to get some of these half completed projects moved from the workbench. This 100w dummy load only needs about a half hour more work and today was a good day to do it. I fired up the soldering iron and soldered the remaining ten 1K Ohm resistors onto the board. (shown below)

The next step was to test to make sure all the resistors were secure and see how close to 50 Ohms I would be. I call 50.6 close enough for me.

Now to mount the board into the chassis and complete the solder work to the SO-239 connector and chassis ground.

Mount the top and secure the four rubber feet and we can call this one good.

This is an air cooled unit. The documentation states 100w continuous with high loads possible for shorter durations. Considering 100w is as much power as I have, this will do fine. I connected it to my FT-897. Yep…it worked and did exactly what it should. I tested up to 100w and the resistors heated up slightly with a 30 second transmit cycle.

Both the 100w and the two 10w dummy loads were fun to build. Today I ordered a nixie tube clock kit and it should arrive in the next week or two. Tomorrow I’m checking out a new amateur radio club I’m considering joining. So stay tuned…lots to blog about.

Until next time…

73 de KD0BIK