Posts Tagged ‘Elecraft’

Part 2 of the K3 surgery.

Part 2 of the K3 surgery.

| It's time for the surgery |

| Beware of other components |

| Front control head removed |

| Fume trap and soldering iron ready |

| Trimming the header pins |

| The two stubborn pins |

| After using Hakko 808 |

| Old out and new ready |

.

Doing surgery on the Elecraft K3 part 1

Doing surgery on the Elecraft K3 part 1

| It's time for some surgery. |

First off an anti static mat with a wrist strap, when dealing with state of the art radios this is a must! A medium quality soldering station makes your soldering jobs a pleasure. I have the WellerWES51, this is a nice temperature controled unit. The tips can be changed out for varied soldering jobs and what's nice with this grade of soldering stations the tips heat up very fast and stay hot.

A soldering station would not be complete without some solder. I have in the past built the Elecraft KX1, 2 Elecraft K2's and at least 25 or more other projects having to do with ham radio. The solder I use is what's called SN63PB37. So what does this mean..........it's make up is 63% tin and 37% lead. This solder flows well and does not take real high temps to get it flowing. For the job at hand with my K3 I am using a diameter of .020. Also a good idea is to get a nice solder stand. The one I have was reasonably priced and allows me too gently pull and I have enough solder. I am not fighting with tangled solder or solder that keeps

You can save some cash by double checking.

You can save some cash by double checking.

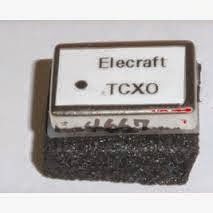

Over the past few weeks I had put some extra dust gathering ham gear up for sale. The sale was a successes and I ended up making 400.00 ham bucks. My main purpose for selling off some gear was to gather the funds for the new Elecraft K3 synthesizer (KSYNA3A as it's called) Without going into detail…..it's a very nice upgrade to the already great K3. While at the Elecraft site I was looking at what else the my K3 could do with in regards to upgrades. I came across the high stability ref oscillator called the KTCXO3-1, it would be a great addition since I am now getting more into the digi modes and the less frequency drift the better. It's a 100.00 dollar upgrade and I wanted to do some more research on the topic before dishing out the cash! I ventured over to Google and typed it in, low and behold one of the sites that came up was VE3WDM blog!! Hmmm did I post about this at some time?? Off I went to my site and to my shock I found out I ordered the KTCXO3-1 when I ordered my new K3. It sure was good I looked into this before placing my order but having said that Elecraft is a great company and after explaining my realization I have had no problem sending it back. I'm getting older so the memory is getting shorter.

ARRL CW Contest done QRP style

ARRL CW Contest done QRP style

| Oliver is asking……"Ahhhh dinner!!! |

| The rig setup |

Score rundown is as follows

Contacts DXCC's Points

81 39 9360

The equipment used was the Elecraft K3 with 500,400 and 250 inrad filters, the Elecraft P3, Begali Contour Key and the Flex control external VFO knob and last but not least the MFJ 1788 Magnetic loop antenna. The software used were N1MM+ contest software, N4PY rig control software and MRP40 CW code reader for the chain saw speed code. I never had Murphy pay me any visits during

| The contest software |

It’s a cold one out there!

It’s a cold one out there!

| Steam coming off the water down at the lake |

| The little motor in the antenna |

It’s time for the Kool-Aid…..:)

It’s time for the Kool-Aid…..:)

| It's like the Borg connected to the collective! |

| New software loading |

All in all – a good day!

All in all – a good day!

There were a lot of things to get done before playing in FYBO, and (channelling Yoda) get them done I did. Believe it or not, my FYBO operation was from the street in front of our house. I live on a relatively quiet side street, so there was no danger of being hit by a car or something like that. I opened up the hatch of the Jeep, just like I do at work, and set up my nylon camping chair and used the "trunk" of my Jeep as an operating table. My antenna was the Buddistick/magmount combo on the roof . I'm sure the neighbors were staring - wondering, "What the heck is he doing now? And what is that tall stick poking up from his car roof?" "And why is our dishwasher going crazy - I'll bet it's him!"

As I set up it was flurrying slightly and the temp was 35F (1C). And then it happened. I tried tuning up the KX3 and couldn't get a decent match. Of course these things always happen at the worst time! Calmly, I took the Buddistick off the roof and inspected it - no problems there. Then the magmount - AHA! Where the coax meets magmount, the dielectric foam surrounding the center conductor wire cracked open (from the cold, I guess, because I keep it in the trunk when not in use). The shield was ever so slightly touching the center conductor and was making for a bad situation. A quick trip to the basement shack was in order. I cut the coax back, soldered on two new ring terminals and put everything back together. The KX3 was a happy camper with a 1:1 match.

In about two hours of operating, here's my summary:

W2LJ

Team Polar Bear

Field - Yes

Category - Single Op

Alternative Power - No (Batteries- Mains charged)

Lowest Temperature - 35

QRPp - No

Final Score - 7780 points

BAND QSOs SPCs NQ7RP Stns

------------------------------------

20 15 12 0

14 10 8 1

------------------------------------

TOTAL: 24 20 1

Score - (24X20) (X4 Temp multiplier) (X4 Field Multiplier) +100 =7780

15 Meters was pleasantly active, affording me 10 of my 24 QSOs. 20 Meters was also busy but noisier, with some TN QSO Party stations and some SOTA stations thrown into the mix. I also was contacted by an SKCC station - I guess they have something going on this weekend, as well as one DX station - G4OBC. I tuned around 40 Meters at the end of my operating time, but heard no FYBOers.

There was no wind to speak of, so it actually didn't feel that bad outside. I think the temperature reached a max of 38F (3C) while I was out. I was comfortable, except that my hands were cold, as I really couldn't send Morse while wearing heavy Winter gloves. And another discovery - the older you get, the more bathroom breaks you need when it's cold! Too much information? Sorry!

Now, if that wasn't enough - my FYBO day was made even better by finally working K1N with 5 Watts. YES!!! I came down to the shack this evening to enter my FYBO log into my Master Log. While doing that, I heard K1N on 20 Meters (haven't worked them there yet) and they were truly 599 loud. I double checked my power setting to make sure I was at 5 Watts and I jumped into the pileup. In about somewhere between 5 to 10 calls, I finally heard my call come back to me. Sweet! My personal goal is now complete. I got K1N in the log for an ATNO, and I also got them in the log using QRP power.

It was a good QRP day. A VERY good QRP day!

72 de Larry W2LJ

QRP - When you care to send the very least!

As I set up it was flurrying slightly and the temp was 35F (1C). And then it happened. I tried tuning up the KX3 and couldn't get a decent match. Of course these things always happen at the worst time! Calmly, I took the Buddistick off the roof and inspected it - no problems there. Then the magmount - AHA! Where the coax meets magmount, the dielectric foam surrounding the center conductor wire cracked open (from the cold, I guess, because I keep it in the trunk when not in use). The shield was ever so slightly touching the center conductor and was making for a bad situation. A quick trip to the basement shack was in order. I cut the coax back, soldered on two new ring terminals and put everything back together. The KX3 was a happy camper with a 1:1 match.

In about two hours of operating, here's my summary:

W2LJ

Team Polar Bear

Field - Yes

Category - Single Op

Alternative Power - No (Batteries- Mains charged)

Lowest Temperature - 35

QRPp - No

Final Score - 7780 points

BAND QSOs SPCs NQ7RP Stns

------------------------------------

20 15 12 0

14 10 8 1

------------------------------------

TOTAL: 24 20 1

Score - (24X20) (X4 Temp multiplier) (X4 Field Multiplier) +100 =7780

15 Meters was pleasantly active, affording me 10 of my 24 QSOs. 20 Meters was also busy but noisier, with some TN QSO Party stations and some SOTA stations thrown into the mix. I also was contacted by an SKCC station - I guess they have something going on this weekend, as well as one DX station - G4OBC. I tuned around 40 Meters at the end of my operating time, but heard no FYBOers.

There was no wind to speak of, so it actually didn't feel that bad outside. I think the temperature reached a max of 38F (3C) while I was out. I was comfortable, except that my hands were cold, as I really couldn't send Morse while wearing heavy Winter gloves. And another discovery - the older you get, the more bathroom breaks you need when it's cold! Too much information? Sorry!

Now, if that wasn't enough - my FYBO day was made even better by finally working K1N with 5 Watts. YES!!! I came down to the shack this evening to enter my FYBO log into my Master Log. While doing that, I heard K1N on 20 Meters (haven't worked them there yet) and they were truly 599 loud. I double checked my power setting to make sure I was at 5 Watts and I jumped into the pileup. In about somewhere between 5 to 10 calls, I finally heard my call come back to me. Sweet! My personal goal is now complete. I got K1N in the log for an ATNO, and I also got them in the log using QRP power.

It was a good QRP day. A VERY good QRP day!

72 de Larry W2LJ

QRP - When you care to send the very least!